Brim offers open pocket washer/extractors, pass-thru dryers, used & rebuilt equipment, spare parts, and technical support. We have the products, the people, and the experience to find the solutions to your equipment needs.

The Markets We Serve

Brim provides Equipment, Parts, and Ancillary Services to Commercial and Industrial Laundries serving the following markets:

Industrial

Uniforms, Shop Towels, & Associated Products

Linen Supply

For Food & Beverage Establishments

Hospitality

Hotels & Lodging

Healthcare

Garments, Linen, & Surgical

Dust Control

Mats, Mops & Towels

Specialty

Military, Prisons & Apparel Manufacturers

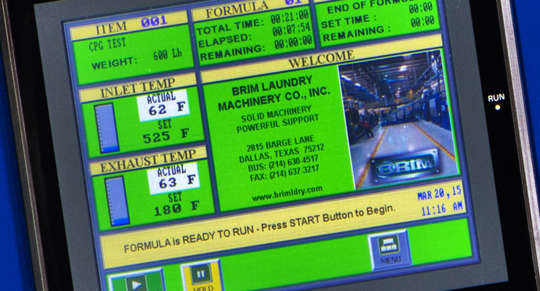

How Our Machines Are Constructed

A Brim machine is designed to take a pounding, but is also simple to maintain and repair. It is built with heavy duty steel material, along with high-tech components, and is welded and inspected by experienced in-house personnel for quality assurance. In short, a Brim machine is made to deliver long lasting performance and durability to meet the demands of your operation.

Where They’re Made

All our products are manufactured in an efficient 250,000 square-foot plant that is centrally located in the U.S. A flow through production line is set up for smooth material handling and machine assembly in a bright and comfortable environment for our well trained staff.

Brim Laundry Machinery Co., Inc. maintains an ETL Listed Mark on our machinery that indicates they have been tested by Intertek and were found in compliance with the requirements of the standards for Industrial Control Panels (UL 508-A).

Brim Laundry Machinery Co., Inc. maintains an ETL Listed Mark on our machinery that indicates they have been tested by Intertek and were found in compliance with the requirements of the standards for Industrial Control Panels (UL 508-A).